In the modern world of manufacturing, where precision and reliability are essential the spindle is one of the most important components of any machining system. The machining spindle is responsible for speed, precision and consistency, whether you are carving high-grade aerospace alloys, or fine tuning components which require high tolerances.

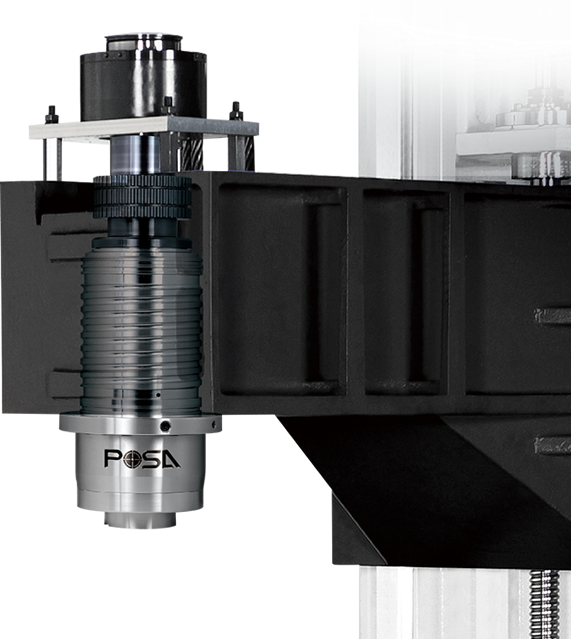

The top spindle makers, such as POSA are leading this specialized industry, changing the quality and endurance of industrial machining environments.

Why the Spindle Is the Heart of the Machine

Each CNC machine is as efficient as the spindle it is mounted on. The spindle is the engine that drives the tool with high precision, stability, and torque. A badly designed or incorrectly aligned spindle can result in malfunctioning parts. It could damage the machine, reduce time-to-market, and shut off the entire production process.

Image credit: posa-spindle.com

This is where precision technology spindles can make all the difference. In contrast to standard components that are mass-produced, and then glued together on the fly precision spindles are precisely engineered, tested, and calibrated to work in extreme conditions and on high demand.

POSA Machinery: More Than A Spindle Manufacturer

POSA Machine has been an innovator in spindle manufacturing for decades. Although many spindle makers claim to be highly precise, they lack the experience and expertise in engineering that POSA has acquired over the years. POSA is well-known for its rigorous internal testing procedures, dedication to international standards and their ability to develop performance-driven solutions that are able to meet the demands of different industries.

POSA spindles can be found in a wide range of machines, from vertical and horizontal machining centres to tool grinding machines. Every spindle is backed an extensive R&D process that is not just on the functionality of the machine but also on the long-term reliability, thermal stability.

The Evolution of the CNC Lathe Spindle

In recent times, the CNC lathe spindle’s innovation has been remarkable. Not just a rotational axis; today’s spindles are incorporating sensors along with cooling systems, as well as smart balancing mechanisms. POSA CNC spindles offer a great illustration. They combine high-speed capabilities and exceptional torque with precision and rigidity, which allows machinists the ability to work with both delicate metals and materials. These spindles, which are made from high-quality steel as well as advanced ceramic bearings, reduce thermal expansion while maintaining tight tolerances over long runs. This dependable design results in greater quality of the part and reduced downtime.

Specialized Machining Spindles that meet real-world Demands

There’s no universal size for spindle for machining, especially in fields such as die and mold manufacturing as well as aerospace, automotive and. POSA is aware that each application has its own specifications. This can be related to spindle speed, load capacity as well as environmental resistance. They offer custom spindle configurations in accordance with the particular requirements of each customer. POSA offers the support for engineering and flexibility that modern companies demand, whether it is creating a vertical milling spindle or incorporating a high-frequency spindle in a compact system.

More Than Machines: A Commitment To Craftsmanship

The POSA philosophy is what separates it from other spindles. The company is dedicated to combining technology and craftsmanship. Their design engineers work closely with customers take note of their pain points and constantly adapt their products to keep ahead of market trends and demands. A good spindle is crucial in an age when machines’ uptime, consistency, and precision can be the difference between a successful and unsuccessful production lines.

Final Thoughts

The future of manufacturing rests not only on machines that are faster but also on components that are more sophisticated and durable. POSA Machine is an excellent example of what spindle makers can accomplish when they combine their technical expertise and a customer-first mindset. Whether you need a high-performance CNC lathe spindle, a heavy-duty machining spindle, or a finely tuned precision spindle, choosing the right spindle isn’t just a detail it’s a decision that shapes everything downstream.